Industrial Applications with QuellTech Laser Metrology

▶ Weld Seam Tracking & Inspection

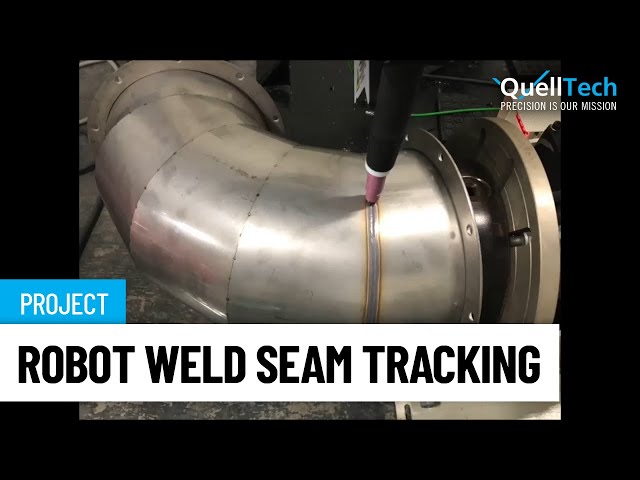

Are you having problems with robot-guided welding like thermal warping? Would you like to carry out a weld seam inspection? Make your welding process more efficient by checking welding errors with the QuellTech laser scanner during your welding process and not just when the welding process is finished and no more corrections are possible.

-

Automatic Weld Bead Inspection by Detecting Cavities and Bumps on the Surface

-

Gap Tracking Application with QuellTech Q4

-

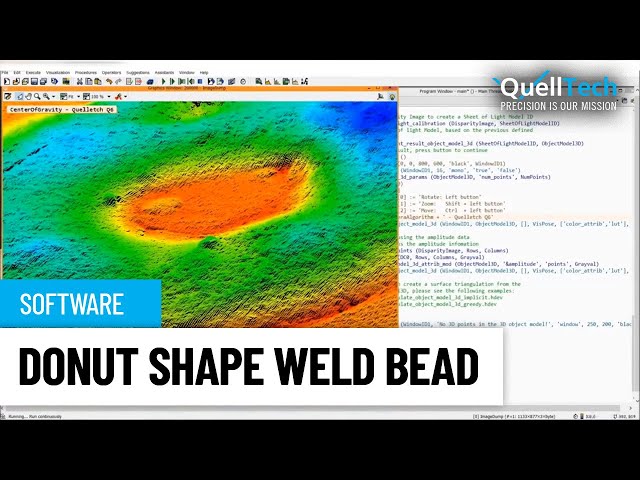

Battery Donut-Shape Weld Bead Inspection with QuellTech Q6

-

Weld Bead Inspection of Welded Gear

-

Weld Seam Tracking with Robot Welding

-

Laser Weld Bead Inspection System

-

Automatically Detecting Holes or Spatters with Laser Scanners

-

Robot Weld Seam Tracking on Bent Pipe

▶ OEM Integration Machine Builder

We support machine manufacturers with our laser measurement technology to improve their quality inspection in production. These solutions can also be implemented as retrofits in existing machines.

-

Inspection of Forgings (Schmiedeteilen)

-

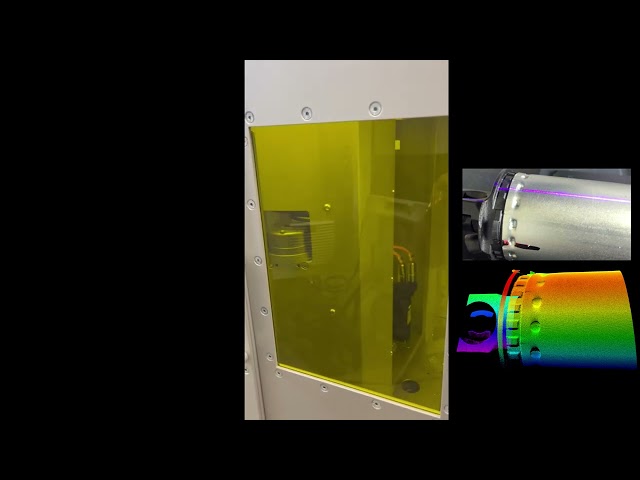

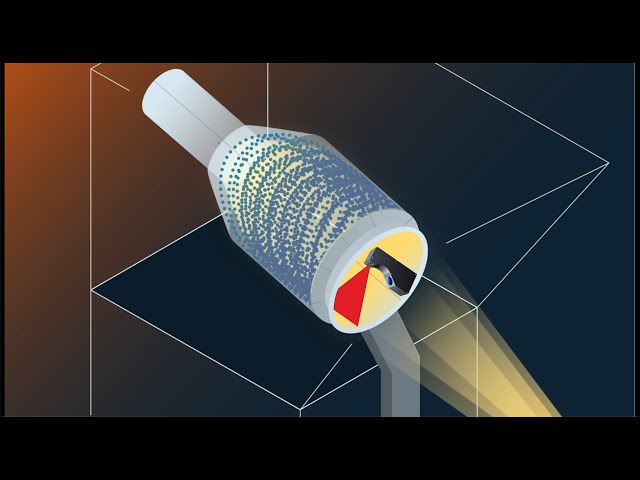

Q6 Scanning Machine Part in Multi Sensor System

-

Continuous Casting Line: Glowing Cast Width and Height Measurement

-

Automated Quality Control for Pipeline Construction in Oil and Gas Industry

-

Weld Bead Inspection of Welded Gear

-

Radius Measurement After Deburring and Edge Rounding Sheet Metal Parts

-

Fully Automated Steel Ingot Inspection

-

Aluminium Ingot Inspection

▶ Metalworking

For QuellTech Laser Scanners, metal surfaces are cooperative materials. Using special algorithms, possible reflections can also be overcome on shiny surfaces. This is important, for example, for applications such as radius measurement after deburring and edge rounding of components, or if you want to detect wear on a roller surface. It is even possible to measure height and width of glowing steel castings.

-

Aluminium Ingot Dimension Check and Surface Inspection

-

Surface Quality Inspection System

-

Continuous Casting Line: Glowing Cast Width and Height Measurement

-

Trajectory Extraction for the Robot

-

Flatness on Steel Parts

-

Shaft Diameter Measuerement with 2D Laser

-

Radius Measurement After Deburring and Edge Rounding Sheet Metal Parts

-

Ingot Measurement with 2D Lasers

-

Flatness Measurement on Gasket Surface

-

Gear Wheel Inspection with Laser Scanners

-

Aluminium Ingot Inspection

-

Fully Automated Steel Ingot Inspection

▶ Continuous Materials

Inline detection of defects on metal cable brake lines and hydraulic tubes. Improves quality assurance in production of continous materials.